PLASTICS IN THE AUTOMOTIVE INDUSTRY: ALL-ROUDERS FOR TOMORROW’S MOBILITY

Part 1 of the series ’Focus on User Industries: Automotive’

Exclusively for K-Mag

This article was published originaly in K-Mag Community News (k-online.com) 9.7.2025. Published here in this magazine with permission of K Messe Duesseldorf.

What do bumpers, door panels and cable sheathing have in common? They are often made of plastic – and for good reason. In the automotive industry, this material has long been more than just a substitute for metal or glass. Plastics save weight, protect components, enable complex shapes and open up new design possibilities.

In part 1 of our series, we show where and how plastics are used in cars – and what they do there. Part 2 highlights how exhibitors at K 2025 are picking up on these developments and taking them further.

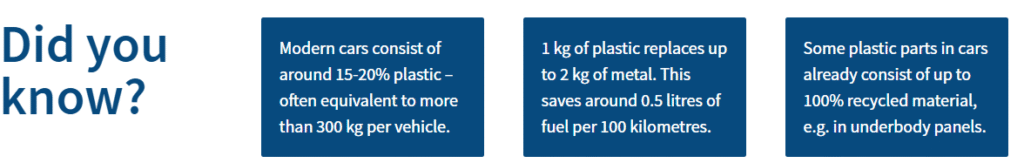

Every modern vehicle now contains several hundred kilograms of plastic. This makes the automotive industry one of the most important customer industries for plastics processing. At the same time, innovations in plastics technology are shaping the transformation of mobility. Whether it’s electric cars, lightweight construction or smart interiors: without plastics, little would be possible.

Where Plastics are Used in Cars

Plastics are not only everywhere in cars – they also perform a wide variety of tasks. Some are visible, others work behind the scenes. And often they have to do more than you might think at first glance.

Plastics in the interior:

- Dashboards, centre consoles, door panels

- Seat shells, trim parts, air vents

- Surfaces with haptic quality and functionality

The design possibilities are enormous: plastics can be textured, coloured, foamed or combined with other materials. They contribute to brand identity and increase ease of use.

Picture above: In the interior, plastics ensure comfort, ergonomics and individual design. Copyright: RomanR – stock.adobe.com

Plastics in the exterior:

- Bumpers, mirror housings, lighting components

- Wheel arches, underbody panels

- Increasingly also structurally relevant parts made of fibre-reinforced plastic

These components must be lightweight, robust and weather-resistant. Many of them are made of thermoplastic polymers, which are easy to process and recycle.

Picture above: Plastic exterior components are not only efficient to manufacture, but also easy to repair or replace. Eвгений Bершинин – stock.adobe.com

Plastics in technical components:

- Cable sheathing and connectors

- Housings for sensors and control units

- Fuel lines, containers, tanks

Plastics insulate, seal and withstand high temperatures. In high-voltage electrical systems in electric vehicles, they provide reliable protection against overvoltage and short circuits.

The areas of application show that plastics are not just an accessory. They are a central element in vehicle construction – functional, lightweight and versatile.

Picture above: Technical plastic components provide protection, insulation and temperature resistance. Copyright: sarymsakov.com – stock.adobe.com

Innovation and Efficiency: Why Plastics are Used in Cars

The demands placed on vehicles are increasing. They are expected to be more efficient, lighter, quieter, safer and more sustainable – ideally all at the same time. Plastics make a decisive contribution to this. Today, they are a driver of innovation for the automotive industry.

Lightweight construction is the key word here. Plastics such as polyamides, polycarbonates and fibre-reinforced thermoplastics help to reduce weight – and thus save energy. Less mass means lower consumption, whether in combustion engines or electric cars. Every kilo saved counts, especially in battery and hybrid vehicles.

The transition to electric mobility in particular is opening up new areas of application. High-voltage cables, battery housings, sensor components – all of these require high-performance plastics.

Plastics are also playing an increasingly important role in acoustics and vibration damping. They ensure a smoother ride – and make the difference audible, especially in quiet electric vehicles.

Plastics also score points in trerms of design and function:

- They allow complex shapes to be produced in one piece

- They enable multitiple functions to be integrated into single component

- They offer scope for new interior designs concepts

Picture above: Plastics and design go hand in hand. Copyright: Messe Düsseldorf

Sustainability and Regulation: ELV Directive as a Game Changer?

The EU End-of-Life Vehicles Directive sets new targets for the use of recycled materials and ease of dismantling. Copyright: Plastics Europe

Plastics in cars not only have to be technically convincing – they are also increasingly coming under regulatory pressure. The new Directive on end-of-life vehicles (ELV Directive) is bringing change. Its goal: more recycling, longer usability, less resource consumption.

Picture above: The EU End-of-Life Vehicles Directive sets new targets for the use of recycled materials and ease of dismantling. Copyright: Plastics Europe

The ELV Directive was politically agreed upon by the EU Environment Council on 17 June 2025. It is currently still in the legislative process – an agreement with the European Parliament and the EU Commission is expected by the end of 2025.

Once the ELV Directive has been adopted, there will be a transition period of five years. The new requirements would therefore become mandatory from around 2030. However, it is already clear today that the directive will bring about significant changes in the design, production and recycling of vehicles, particularly with regard to the use of plastics.

Key points of the ELV Directive:

- 25% of plastics in new vehicles must come from post-consumer recyclates.

- Vehicle components such as bumpers, cable harnesses and tanks must be easier to dismantle and recycle.

- Digital recycling passports and standardised recycling certificates are intended to ensure greater transparency.

For the plastics industry, this means it must deliver solutions – in material development, design for recycling and processing methods. Mechanical recycling alone is not the only way forward. Chemical and solvent-based recycling, the use of bio-based raw materials and CO₂ as a carbon source are also coming into focus.

The challenges are considerable:

- Consistently high-quality recyclates

- Cost and supply security

- Recognition of new recycling processes in regulations

… but so are the opportunities:

- Development of new markets for secondary raw materials

- Partnerships along the value chain

- Development of circular business models

The regulation could thus become a lever – not only for more sustainable vehicle production, but also for a more robust plastics industry in Europe.

Outlook: Plastics Expertise Meets Mobility Needs

Plastics have become indispensable in the automotive industry. Their low weight, high strength and design flexibility make them the ideal material for a wide range of requirements. And less weight means lower energy consumption – and thus lower CO₂ emissions when driving.

As their importance grows, so do the requirements – technical, economic and regulatory. But the industry is responding. It is developing new materials, recycling solutions and concepts for the circular economy. Much of this is being done in collaboration with OEMs, suppliers and research institutions.

This dynamic is also evident at K. Here, companies from across the value chain are presenting what plastics can achieve in vehicle construction today and tomorrow

Picture above on the right: At K, exhibitors show how plastics are contributing to the transformation of mobility – from new materials to circular production solutions. Copyright: Messe Düsseldorf

One thing is clear: The mobility transition needs plastics – and K is the place where it becomes clear how this connection can be achieved.

Author: Elena Blume | K-Mag

Author: Elena Blume | K-Mag

Elena Blume has been writing for various industry magazines for eight years and joined the K-Mag editorial team in 2021. She is particularly interested in topics related to innovative plastics solutions that contribute to sustainability and address current challenges relevant to industry and society.